IV) cannot be used in machines with liquids or humidity maintained above 95%. III) it shall be installed where the temperature will not rise above the maximum service temperature after the Miniature Thermal Cutoff Devices is blown. II) when selecting the installation position of the fuse, pay attention not to transfer the stress to the fuse due to the vibration in the finished product and the displacement of other accessories. I) The rated current and voltage, fusing temperature (TF), service temperature (th) and maximum temperature (TM) of each temperature fuse shall be used under the specified parameters. The following items must be observed to ensure the normal operation of the Thermal Switches: In this way, the circuit is permanently cut off. When the temperature around the temperature fuse rises to its operating temperature, the fusible alloy melts and shrinks into a ball at the ends of the two pins under the action of surface tension and the help of special resin. The current can flow from one pin to another. The third type: square shell Thermal CutoffsĪ section of fusible gold wire is connected between the two pins of the temperature fuse, and the special resin is coated with the fusible gold wire.

When the melting point is reached, with the help of the resin mixture (increasing the surface tension of the melted alloy), the melted alloy rapidly shrinks into a ball centered on the leads at both ends under the action of surface tension, so as to permanently cut off the circuit. When the ambient temperature rises, the specific resin mixture begins to liquefy. It is composed of an axisymmetric lead, a fusible alloy that can be melted at a specified temperature, a special compound to prevent its melting and oxidation, and an insulating porcelain insulator. The second type: porcelain tube type thermal fuse The circuit is opened and the current between the sliding contact and the left lead is cut off. That is, the spring expands and the sliding contact is separated from the left lead. When the external temperature reaches a predetermined temperature, the organic matter can melt and the compression spring will become loose. Before the temperature fuse is activated, the current flows from the left lead to the sliding contact and through the metal housing to the right lead.

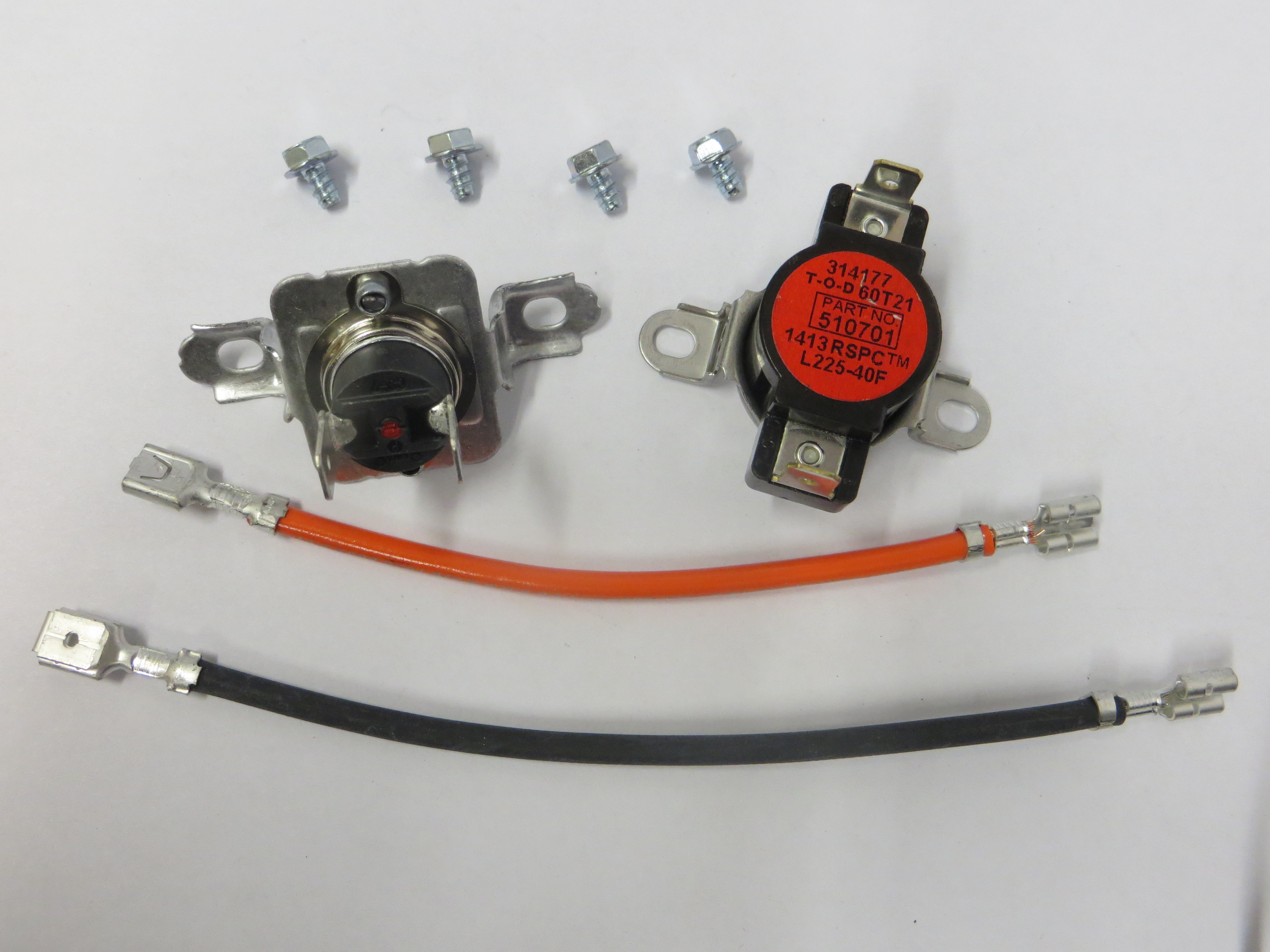

It is composed of sliding contact, spring and electrically nonconductive thermal pellet. There are many forms of temperature fuse, and the following three are more common:

0 kommentar(er)

0 kommentar(er)